In the modern world, laser printers have become an integral part of our daily lives, enabling us to produce high-quality text and images with remarkable speed and precision.These machines have revolutionized the way we produce documents, offering high-speed, high-quality printing. But have you ever wondered how laser printers work their magic? In this blog post, we’ll dive into the fascinating world of laser printers and explore the technology behind their functioning.

Basic Components Of A Laser Printer

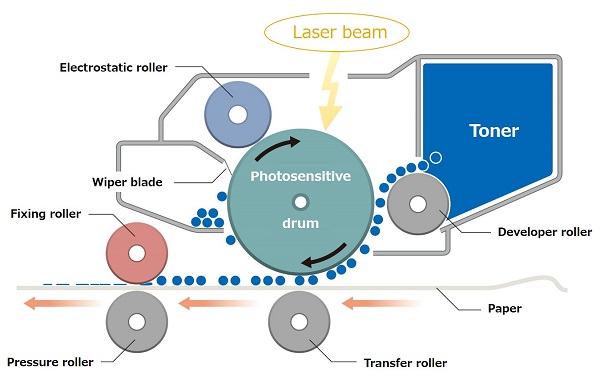

Laser printers are widely used in offices and homes for high-quality printing. They work by using a laser beam to create an electrostatic image on a photosensitive drum, which is then transferred onto paper using toner. The paper is then fused with the toner using heat. The basic components of a laser printer include:

Photosensitive Drum

This is a critical component that receives the laser’s light. The drum is coated with a photosensitive material that becomes charged where the laser hits it. This charged area attracts toner particles to form the image.

Laser Assembly

The laser assembly emits a laser beam that’s directed onto the photosensitive drum. The laser beam selectively discharges the charged areas of the drum’s surface, creating a pattern corresponding to the content to be printed.

Toner Cartridge

Toner is a fine powder containing pigments that form the image on the drum. The toner cartridge holds the toner and releases it onto the drum in response to the drum’s electrostatic charge pattern.

Developer Unit

This unit includes a set of small, negatively charged beads that are mixed with the toner. The developer unit charges the toner particles, ensuring they are attracted to the oppositely charged areas on the drum’s surface.

Transfer Corona Assembly

After the drum is coated with toner, the image is transferred from the drum to the paper. The transfer corona assembly creates an electrostatic charge on the paper that attracts the toner particles from the drum.

Fuser Assembly

The fuser assembly consists of heated rollers. After the toner has been transferred to the paper, it passes through the fuser assembly, where heat and pressure fuse the toner particles onto the paper’s surface.

Paper Feed System

Laser printers have mechanisms to feed paper from a paper tray into the printing area. This system includes rollers that help move the paper through the various stages of printing.

These components work together to produce high-quality printed documents efficiently. Keep in mind that there might be variations in design and features across different laser printer models, but the fundamental components mentioned above are common to most laser printers.

Electrophotography Process – The Inner Workings Of A Laser Printer

Electrophotography, commonly known as the electrostatic printing process or the xerographic process, is the underlying technology behind laser printers. This process involves several steps that enable the creation of high-quality printed output. Here’s a detailed overview of the inner workings of a laser printer using the electrophotography process:

1. Charging

The process starts with the photosensitive drum, which is coated with a layer of photoconductive material. The drum’s surface is uniformly charged using a charging corona wire or roller. This creates a consistent negative charge across the drum’s surface.

2. Exposure

The laser assembly emits a laser beam that is modulated to match the content to be printed. The laser selectively discharges specific areas on the drum’s surface, creating a pattern of positive and negative charges. The discharged areas correspond to the white areas of the final image.

3. Developing

The developer unit consists of small, negatively charged beads (toner) that are mixed with the toner particles in the toner cartridge. The developer unit uses electrostatic attraction to transfer the toner particles onto the charged areas of the drum’s surface. The toner adheres to the areas discharged by the laser, forming the latent image.

4. Transfer

A piece of paper is fed from the paper tray into the printer. The transfer corona assembly creates a strong positive charge on the back of the paper. This positive charge attracts the negatively charged toner particles from the drum’s surface, transferring the toner image from the drum onto the paper.

5. Fusing

The paper now carries the toner image, but the toner is only loosely attached. The paper passes through the fuser assembly, which consists of heated rollers. The heat and pressure from the rollers melt the toner particles and fuse them permanently onto the paper’s surface. This produces a durable and smudge-resistant image.

6. Cleaning

After the transfer, residual toner particles might remain on the drum’s surface. To prepare the drum for the next printing cycle, a cleaning blade or roller removes any leftover toner. This ensures that the drum is clean and ready to be charged for the next image.

7. Erasing

To completely remove any residual charge from the drum’s surface after cleaning, an erasing lamp shines a bright light onto the drum. This process ensures that the drum is uniformly charged and ready for the next exposure.

8. Recharging

The drum is once again uniformly charged in preparation for the next printing cycle. The process repeats as necessary for each page of the print job.

Throughout these steps, the controller board of the printer plays a crucial role. It receives the print job data from the connected computer, processes it, and controls the various components of the printer to execute each step of the electrophotography process accurately.

The combination of precise laser modulation, electrostatic charges, toner particles, and heat fusion allows laser printers to produce high-resolution, sharp, and durable printed output efficiently. This process is the foundation of laser printing technology and has been widely adopted for its speed, quality, and versatility.

How Laser Printers Differ From Other Printers

Laser printers differ from other types of printers, such as inkjet printers and dot matrix printers, in several key ways. These differences relate to their printing technology, output quality, speed, cost, and intended use cases. Here’s a comparison of laser printers with other types of printers.

Laser Printers vs. Inkjet Printers

Laser printers and inkjet printers are two common types of printers, each with its own advantages and disadvantages. The choice between them depends on your specific printing needs, budget, and preferences. Here’s a comparison of the two:

Speed

Laser printers are generally faster than inkjet printers, making them suitable for high-volume printing tasks. Inkjet printers are slower compared to laser printers, which might not be ideal for large print jobs.

Quality

Laser printers offer sharp and crisp text output, making them ideal for text-heavy documents. Inkjet printers can produce high-quality color images and are suitable for photo printing.

Cost Per Page

Laser printers tend to have a lower cost per page compared to inkjet printers, especially for monochrome (black and white) printing. Inkjet printers tend to have a higher cost per page, especially for color printing. This can make them less cost-effective for high-volume printing.

Color Printing

While color laser printers are available, they tend to be more expensive than inkjet printers for color printing. However, they are becoming more affordable. Inkjet printers can reproduce a wider range of colors, making them better for color-sensitive tasks like graphic design and photo printing.

Initial Cost

Laser printers generally have a higher upfront cost compared to inkjet printers. Inkjet printers are typically more affordable upfront compared to laser printers.

Ultimately, the choice between a laser printer and an inkjet printer depends on factors such as the type of printing you need, the volume of printing, your budget, and your preference for print quality. If you’re primarily printing text documents with occasional graphics, a laser printer might be more suitable. On the other hand, if you need high-quality color printing and are willing to accept slightly higher per-page costs, an inkjet printer could be the better choice.

Factors Affecting Print Quality And Speed

The print quality and speed of a laser printer can be influenced by various factors, including hardware specifications, software settings, and the type of document being printed. Here are some key factors affecting print quality and speed in laser printers:

Resolution

The resolution of a laser printer is measured in dots per inch (dpi). The higher the resolution, the sharper and more detailed the print will be. Most laser printers have a resolution of 600 dpi, but some high-end models can print at resolutions of up to 1200 dpi or more.

Color depth

The color depth of a laser printer is measured in bits per pixel (bpp). The higher the color depth, the more colors the printer can produce. Most laser printers have a color depth of 24 bpp, which is capable of producing over 16 million colors.

Paper quality

The type of paper you use can also affect the print quality. Laser printers are designed to work best with high-quality paper that is made specifically for laser printers. Using poor-quality paper can result in faded or blurry prints.

Print speed

The print speed of a laser printer is measured in pages per minute (ppm). The faster the print speed, the less time it will take to print a document. The print speed of a laser printer can be affected by the resolution, color depth, and paper type.

Print settings

The print settings you choose can also affect the print quality and speed. For example, choosing a higher resolution will result in a sharper print, but it will also take longer to print.

Printer maintenance

Regularly cleaning and maintaining your laser printer can help to improve its print quality and speed. This includes tasks such as cleaning the printhead, rollers, and fuser.

In general, higher resolution, color depth, and print speed will result in better print quality, but they will also take longer to print. The best way to choose the right settings for your needs is to experiment and see what works best for you.

Maintenance And Troubleshooting Tips

Maintaining and troubleshooting laser printers is essential to ensure they work efficiently and have a longer lifespan. Here are some maintenance and troubleshooting tips for laser printers:

Maintenance

- Clean the printhead regularly. This can be done using a cleaning kit that is specifically designed for your printer.

- Defragment the printer’s hard drive. This can help to improve the printer’s performance.

- Keep the printer in a cool, dry place. This will help to prevent the printer from overheating and malfunctioning.

- Avoid printing on wet or damp paper. This can cause the paper to jam and damage the printer.

Troubleshooting

- If the printer is not printing, check to make sure that it is turned on and that the power cord is plugged in.

- If the printer is still not printing, try printing a self-test page. This will help to determine if the problem is with the printer or with the computer.

- If the self-test page prints, try clearing the printer’s paper jam.

- If the printer is still not printing, check the ink or toner levels. If the levels are low, replace the cartridge.

- If the printer is still not printing, contact the printer manufacturer for assistance.

By following these tips, you can help to keep your laser printer in good working condition and avoid costly repairs.

Conclusion

Laser printers have revolutionized the way we print documents, offering speed, precision, and cost-efficiency. Understanding how they work can help you make informed decisions when choosing the right printer for your needs. From the laser beam to the fuser unit, each component plays a crucial role in the laser printing process, transforming digital data into tangible documents we can hold in our hands.